OVERVIEW

Design

characteristics

DATA SHEET

| GENERATOR | Type | Induction |

| Maximum Power | 65 kW | |

| Rated Power | 55 kW | |

| ROTOR | Configuration | Vertical Axis |

| No. of Blades | 3 or 5 | |

| Blade Material | Glass fibre | |

| Blade Length | 14 m | |

| Rotor Diameter | 14 m | |

| Swept Area | 196 m2 | |

| Nominal Rotor Speed | 34 rpm | |

| Pitch/Yaw | Fixed | |

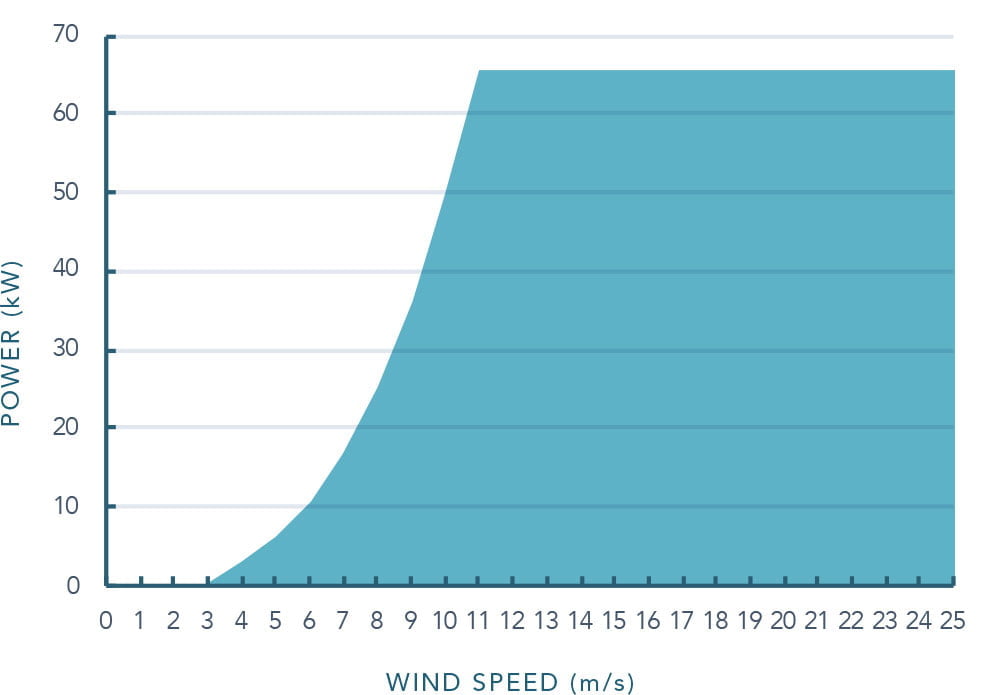

| WIND | Cut-In Speed | 3.5 m/s |

| Rated Wind Speed | 11 m/s | |

| Cut-Out Speed | 25 m/s (Variable) | |

| Survival Speed | 59.5 m/s | |

| WEIGHTS | Hub | 8,200 kg |

| Rotor Assembly | 5,000 kg | |

| Tower | 19,500 kg | |

| TOWERS | Monopole Tripod | 23 – 30 m |

| DESIGN PARAMETERS | Turbine Design Class | IEC 61400-2 Class II |

| Temperature Range | -20° to 50°C | |

| Lifespan & Servicing | 20 years, subject to regular maintenance |

Applications

- Industrial

- Agricultural

- Remote & Island Communities

- Built-Up Environments

- Turbulent Wind Regions

The N-55 is capable of displacing greenhouse gas emissions from 97,000 kg worth of coal burned each year.

Performance

POWER CURVE

Energy output

| Annual Mean wind Speed (m/s) | Estimated Annual Output (kWh) |

|---|---|

| 5.0 | 92,739 |

| 5.5 | 119,676 |

| 6.0 | 147,690 |

| 6.5 | 175,776 |

| 7.0 | 203,178 |

| 7.5 | 229,348 |

| 8.0 | 253,912 |

| 8.5 | 276,628 |

Reliability & Safety

SAFETY

- Base Level: Regenerative braking slows the turbine rotor down while still harvesting energy.

- Second Level: Electronic control system activates mechanical brake.

- Third Level: Quad pneumatic, fail-safe mechanical brakes deploy, bringing the turbine to rest in as little as 10 seconds.

DATA INPUT &

MANAGEMENT

- Integrated microprocessor with multiple sensor inputs: wind speed, power, voltages, currents and phase, rpm, vibration and temperature alerts.

- LCD display in control box. Can output to local PC or be monitored remotely via the internet.

- Remote Monitoring: Allows remote monitoring of the wind turbine in order for Ryse to ensure the turbine is operating at its peak performance.

CONSTRUCTION &

MAINTENANCE

- Limited plant requirement for installation.

- Majority of major components at ground level, simplifying installation, operation and maintenance.

- Environmentally friendly screw pile foundation instead of a concrete foundation.

- Screw pile foundation offeres quick relocation and re-deployment.

- Ryse service contract available.