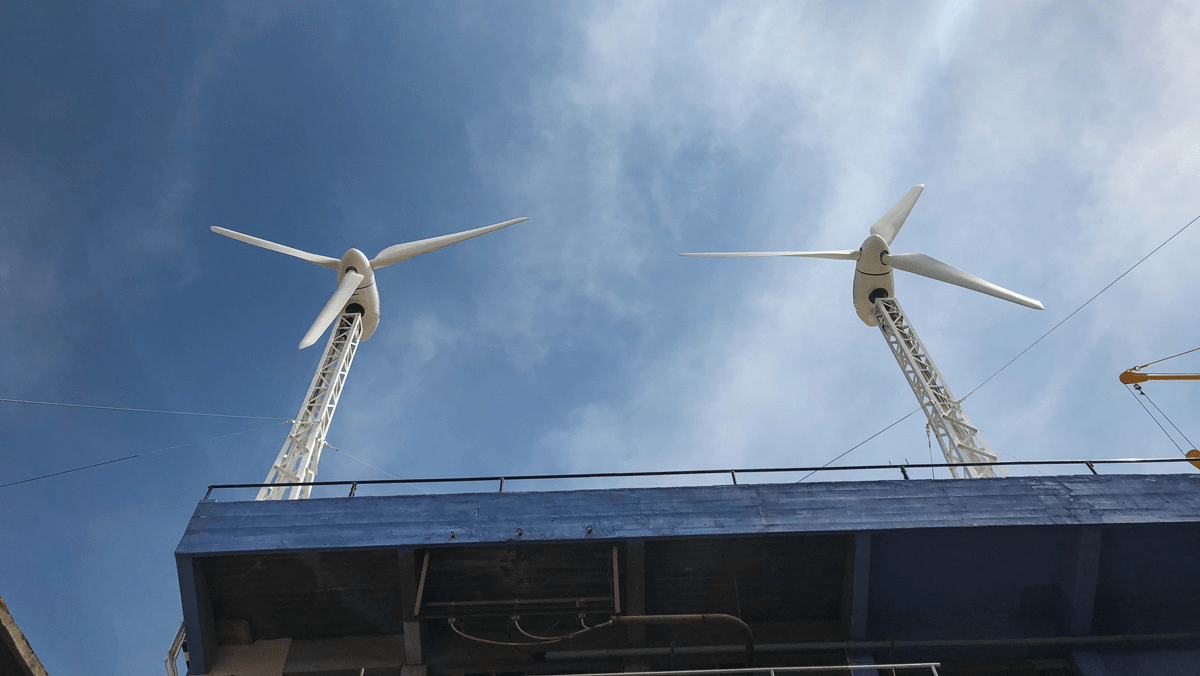

OVERVIEW

Design

characteristics

DATA SHEET

| GENERATOR | Type | Permanent Magnet |

| Maximum Power | 20 kW | |

| Rated Power | 10 kW (Software Limited) | |

| ROTOR | Configuration | Horizontal Axis |

| No. of Blades | 3 | |

| Blade Material | Glass fibre | |

| Blade Length | 4.5 m | |

| Rotor Diameter | 9.8 m | |

| Swept Area | 75.4 m2 | |

| Nominal Rotor Speed | 120 rpm | |

| Pitch/Yaw | Downwind active pitch with assisted yaw | |

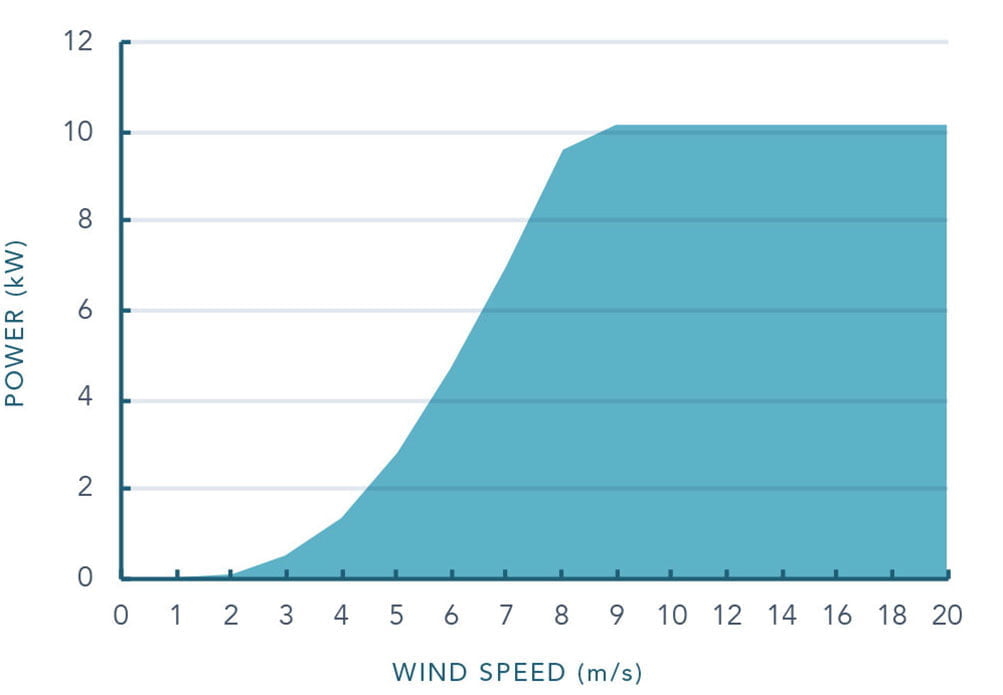

| WIND | Cut-In Speed | 2 m/s |

| Rated Wind Speed | 9 m/s | |

| Cut-Out Speed | 30 m/s | |

| Survival Speed | 70 m/s | |

| WEIGHTS | Nacelle/Rotor | 1,000 kg |

| TOWERS | Lattice | 15 – 36 m |

| Monopole | 18 – 27 m | |

| Tilt-Up | 18 – 27 m | |

| DESIGN PARAMETERS | Turbine Design Class | IEC 61400-2 Class I |

| Temperature Range | -20° to 50°C | |

| Lifespan & Servicing | 20 years, subject to regular maintenance |

Applications

- Industrial

- Agricultural

- Off-Grid

- Micro-Grid

- Remote & Island Communities

- Built-Up Environments

The E-10 is capable of displacing greenhouse gas emissions equivalent to 60 acres of forest each year.

Performance

POWER CURVE

Energy output

| Annual Mean wind Speed (m/s) | Estimated Annual Output (kWh) |

|---|---|

| 2 | 3,160 |

| 3 | 8,257 |

| 4 | 16,911 |

| 5 | 28,507 |

| 6 | 41,271 |

| 7 | 53,454 |

| 8 | 63,870 |

| 9 | 71,854 |

| 10 | 71,854 |

Reliability & Safety

SAFETY

- Base Level: Active blade pitch control, with 90º of movement, limits power output and can put blades in a total stall position.

- Second Level: Electronic control system activates mechanical brake with shaft lock and electromagnetic induction brake.

- Third Level: Passive springs deploy, putting the turbine blades in a stall position, spoiling the rotor aerodynamics and subsequently its ability to rotate.

DATA INPUT & MANAGEMENT

- Remote Control: Allows the remote customization of the wind turbine to provide the optimum performance at every site.

- Storm Detection: Intelligent storm detection algorithm and automatic safety lock protects the turbine in the event of dangerous gusts/hurricane weather.

- LCD display in control box. Can output to local PC or be monitored remotely via the internet.

CONSTRUCTION & MAINTENANCE

- Anti-Corrosive Blades: The blades and nacelle are treated with epoxy paint and hermetically sealed. This gives corrosion and saline protection, making the turbine ideal for island, coastal or desert deployments.

- Ryse Energy service and maintenance contracts available.

- Online store for easy purchase of spare parts & equipment: ryse.energy/shop